|

|

MAIN PAGE MAIN PAGE |

ABOUT US ABOUT US |

REFERENCES REFERENCES |

CONTACT US CONTACT US |

VIDEOS VIDEOS |

|

|

| |

GLASS SANDBLASTING INFORMATIONYou can find information about glass sandblasting machinery and equipment, glass sandblasting techniques on this web page. The process of glass sandblasting can be made by 3 different methods and machinery according to the 3 different needs. Flat glass sandblasting is the first of these needs, the second is curved glass sandblasting and the third is the need for glassware sandblasting. Flat Glass Sandblasting Process Flat glass sandblasting process is usually made by automatic sandblasting machines that runs vertical and contains numerous sandblasting gun. These type of machines are consuming large amounts of air, should be fed with a screw system compressor with air drier. Below example is a flat glass sandblasting system. | |

| Flat Glass Sandblasting Machinery | |

|

|

| Flat Glass Vertical Sandblasting Machine | Screw Compressor Set |

|

|

|

Curved Glass (Shower Cabin Glass) Sandblasting Process Curved glass sandblasting process requires much more complicated system than flat glass sandblasting. If requested curved glass sandblasting at vertical glass sandblasting machines, glass transition width should be increased. In this case, massive amounts of dust comes out of the machine. Therefore, horizontal tunnel-type automatic sandblasting machines are preferred for the curved glass sandblasting. Below example is a tunnel type glass sandblasting machinery developed for curved glass sandblasting. Flat glass can also be sandblasted in this machine, but this type of machine has higher cost than the vertical type sandblasting machine. | |

| Curved Glass Sandblasting Machinery | |

|

|

| Horizontal Glass Sandblasting Machine | Screw Compressor Set |

| |

|

Glassware Sandblasting Glassware sandblasting is the process of making decorative of the glasware by sandblasting. In order to sandblast these type of materials different type of sandblasting cabinets are used. Glassware is placed inside the blasting cabinet and individually sandblasted by hand. In this process, the dust captured by the dust filter on the back of the cabinet. Blasting of sand is done by sandblasting gun. These guns are two types and consume of 0,6-1,2m3/min air. Machinery and compressor set that are required for glassware sandblasting are illustrated below. | |

| Glassware Sandblasting Machinery | |

|

|

| Benchtop Sandblasting Machine | Piston Compressor |

|

|

| Sandblasting Cabinet | Screw Compressor |

|

|

|

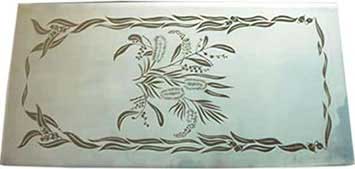

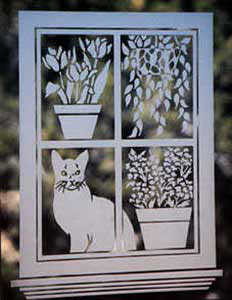

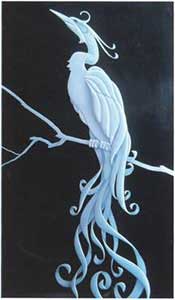

Glass Sandblasting Techniques Surface Etching, Carving and Shading Surface Etching-So named because you are only etching the surface of the glass. In addition, this type of etching is all done in one stage of blasting, which means that the designs produced are all 2 element designs. That is, all the designs are positive and negative, or black and white. The etched portions of the design almost always look white, and the clear, unetched portions of the design look black or dark. All etched elements have to be separated by spaces of unetched glass, or the etched elements blend together as a single silhouette, with no detail inside the border. Surface etching is the easiest technique to learn and the fastest way to produce a finished etching on glass. The etched designs aren't as sophisticated as those from carving or shading. Carving-Called carving because you actually blast, or carve, deep into the glass, giving a three dimensional etching. There are several types of carving, including single stage, two stage, multi-stage, and freehand carving. Single stage carving is simply blasting a surface etching design deeply into the glass, separating elements with clear spaces, as in surface etching. With two stage or multi-stage carving, the resist is removed, not all at once, but a few elements at a time and in a definite sequence. This way, elements can be carved to different depths than the other elements they touch, yielding a 3-D bas relief carving. But not a regular bas relief, a reverse bas relief - since you are carving from one side of the glass and viewing the finished carving from the opposite (smooth) side! In other words, you are carving a hollow (or negative) shape in the glass that looks solid and positive from the smooth side. Shading-Like surface etching, this technique just blasts the surface of the glass. But unlike surface etching, the elements in the design are blasted to different apparent shades of gray (hence the name Shading), rather than to the solid white color produced in surface etching. The principle of shading is that 100% clear glass usually appears dark while full surface etching appears 100% white. So you can create shades of gray by etching the surface to a density less than 100%, and you control the shade by controlling the density. Shading, like carving, can be done in one stage, two stage, multi-stage, and freehand techniques. | ||

| Surface Etching | Carving | Shading |

|

|

|

| ||